Causes

Rapid prototyping of pottery body

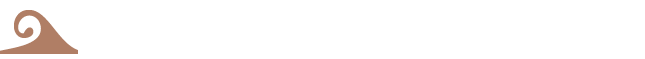

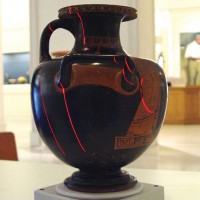

The dimensions of a pot on display in a museum differ from those of the same pot when it came off the potters wheel. During drying , following the throwing of the pot on the wheel, the pot’s dimensions shrink, typically by ~ 10%. Another 2-3% shrinkage occurs during firing. It is therefore essential to take this shrinkage into account when reproducing a museum exhibit. Following a 3D scan of the museum exhibit all dimensions are blown up by ~13%. This 3D model is then 3D printed and provides the shape that the modern potter throws on the wheel. In this way the end result, after drying and firing, conforms to the dimensions of the museum exhibit. This process saves considerable time and labour and ultimately reduces the cost of the reproduction.